A Brief History of the Assembly Line Before and After Ford

People usually mention Henry Ford in the same breath as the words “assembly line.” But although Ford was a great innovator in auto manufacturing, he didn’t invent the assembly line—he just adapted it. In fact, humans have been using assembly lines in manufacturing since at least the 14th century.

This brief history of the assembly line may hold some surprises for people who think assembly lines weren’t effective until robots came along. No worries; we’ll get there. But first, consider some remarkable innovations from the past that transformed assembly lines from pulleys and ropes to full automation.

The Venetian Arsenal: A Pioneer in Assembly Lines

As early as the 14th century, the Venetian Arsenal employed assembly lines to build boats. This military-industrial complex was unique for its time, with an ability to mass-produce galleys using an assembly-line process. At its peak, the Arsenal employed 16,000 workers, making it one of the largest industrial sites in Europe during the 16th century. The workers, known as arsenalotti, were part of a system that was possibly the single largest pre-industrial production line.

Assembly Line Techniques in 18th-Century English Mills

Flour mills in England began to adopt assembly-line techniques in the 1700s. Assembly lines also appeared at facilities in Portsmouth, England, which made ship components—specifically the pulleys for Royal Navy ships. Railway components where created in assembly-line fashion in foundries near the Liverpool and Manchester train lines and the Bridgewater Canal.

Assembly Lines in the Meatpacking Industry

By the late 19th and early 20th centuries, the meatpacking industry in Chicago and Cincinnati had also adopted assembly-line techniques. Carcasses were moved along the line, with workers performing specialized cutting tasks at each stage. This method of production significantly increased efficiency and output in the industry.

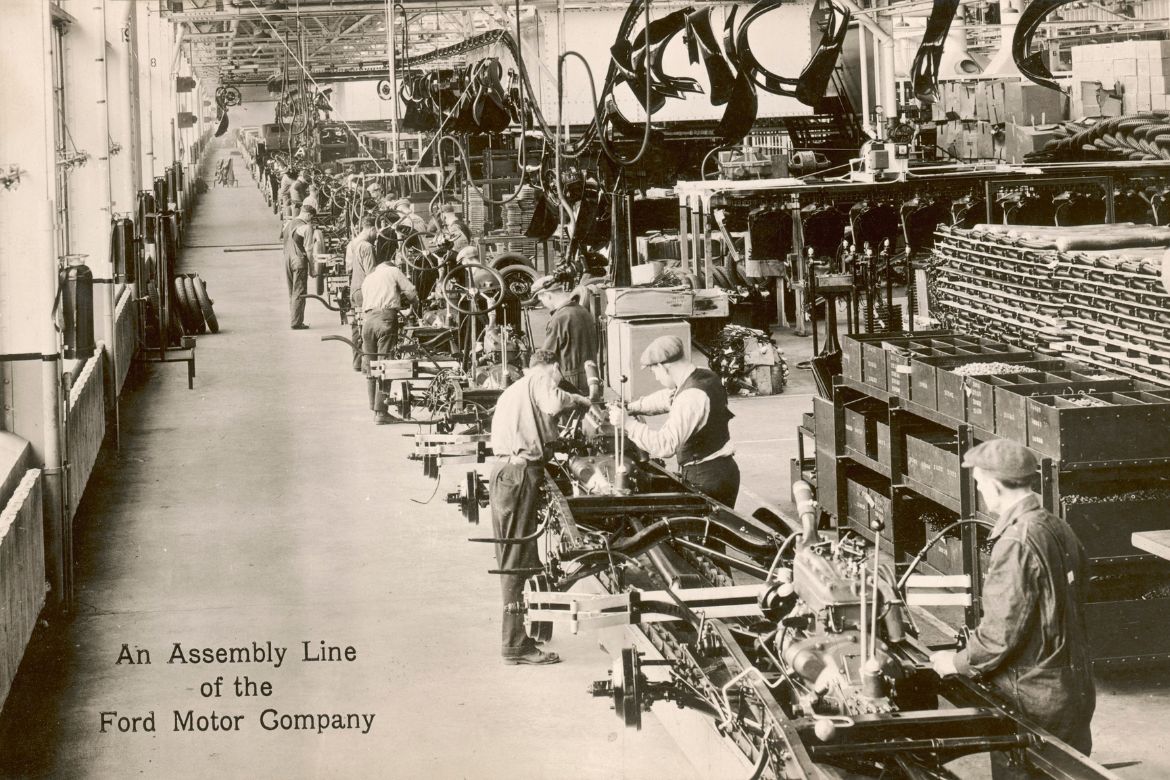

Ford and the Introduction of Conveyor Belts

Henry Ford revolutionized automotive assembly lines by breaking down work into multiple tasks and introducing conveyor belts to move car components. This innovation allowed for quicker, more efficient production, leading to lower costs and higher volumes. Ford’s use of the assembly line became a model for mass production in various industries. Many modern industries still rely on conveyor belts for efficient production.

Robots, 3D Printing, and the Modern Assembly Line

At last, we get robots. These specialized computer-controlled machines have taken on many of the repetitive tasks of assembly-line manufacturing. They can perform tasks with high precision and speed, often surpassing human capabilities in these areas. The incorporation of robotics in assembly lines further enhances productivity and reduces errors, marking another significant milestone in the history of the assembly line. However, in one example where humans are still employed to perform repetitive tasks along auto assembly lines, BMW has taken steps to protect workers’ hands (and arguably their jobs) using inexpensive 3D-printed thumb guards.

The evolution of the assembly line has been a fascinating journey from its beginnings at the Venetian Arsenal to today’s advanced robotic systems. Assembly lines continue to play crucial roles in manufacturing processes worldwide.