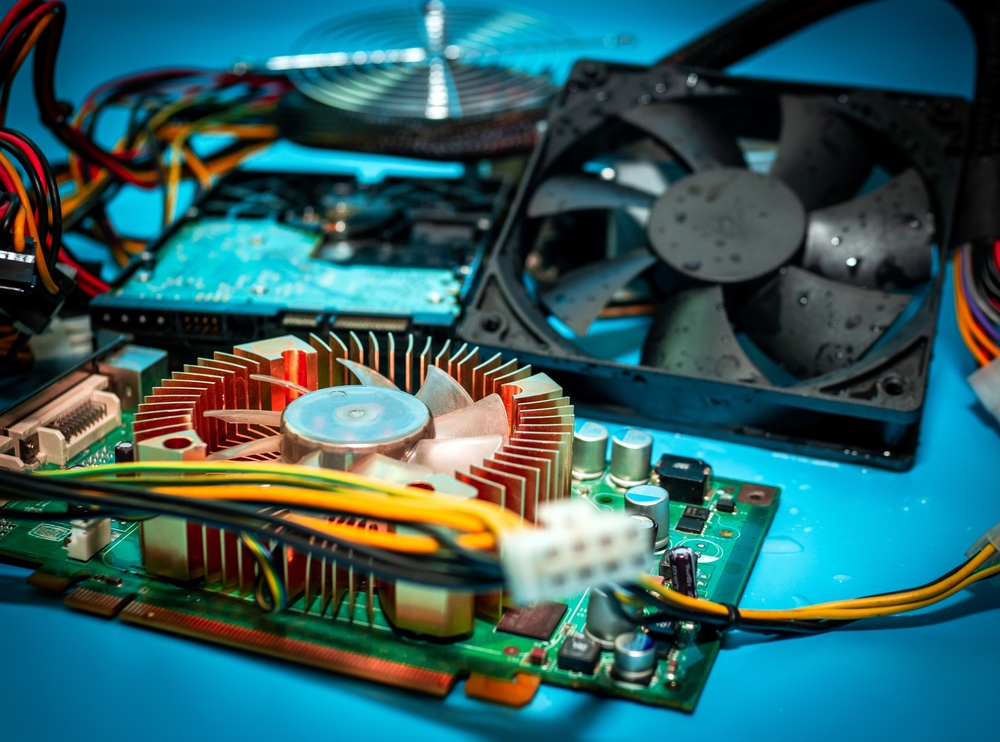

Plastic Injection Molding Is Critical for the Production of Computer Parts

Plastic Injection molding supports low volume production, and is the most widely used manufacturing process globally for low volume manufacturing and high volume production, and it has been in existence for so many years. The process is used to manufacture products such as household appliances, electronic devices, and computer parts. Computer parts operate at high temperatures and therefore, require special types of plastics, that can keep them strong and durable.

Why Plastic Is Used In Computer Parts?

1.Plastic Is Durable

Plastic is a durable material, which can be molded to any shape easily by heating it. Once it cools down, it becomes highly durable. When screwing electronic parts to the computer parts, the plastic must not break down. Therefore, durable plastic is preferred for the manufacturing of computer parts.

2.Plastic Allows Reduced Manufacturing Cost Of Computer Parts

Plastic is an easily obtainable petroleum product, which has high availability in the market. Increased availability in the market allows plastic manufacturers to shrink the cost of production of plastic computer parts, which ultimately reduces the overall cost of a computer even during low volume production.

Moreover, plastic injection molding is a straightforward process, that doesn’t require much investment. As a result, choosing plastic to manufacture computer parts is a smart move to keep the cost of production controlled.

3.Plastic Computer Parts Can Be Later Recycled

There are several government norms in different countries, that focus on e-waste management. While the electronic PCBs require complex waste disposal methods, plastic has an easy way out for waste management. Plastic is very easy to recycle to make less durable products, which is very helpful for any low-volume manufacturer.

Since plastic products are heavily preferred and used all over the world, using plastic from broken or depreciated computer parts to recycle it and make other useful items is a brilliant method to keep the plastic computer waste minimized. Computer brands can easily reduce carbon levels on the planet by using plastic for their computer parts.

What Types Of Plastic Is Best For Computer Parts?

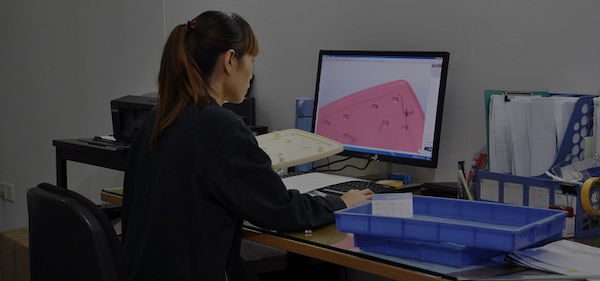

Plastic has a lot of varieties, and choosing the right ones for computer parts is highly crucial. Based on the chemical composition and nature of different types of plastics, below are top 5 ideal choices for making computer parts using injection molding.

1.ABS Plastic

ABS plastic is widely used to manufacture durable goods. ABS is strong, durable, and gives smooth surface finish of manufactured goods to prototype low volume computer parts. ABS plastic can be easily molded to make desired shapes using plastic injection molding.

Furthermore, ABS plastic is preferred when you have to make high precision products such as small and tiny computer parts. Therefore, ABS has a lot of characteristics, making it a perfect candidate for computer parts.

2.ASA + PC Blend

This is an alloy of polycarbonate, that has very exciting properties. For instance, this type of plastic can tolerate high levels of moisture and UV. Electronic chips don’t go well with UV radiation, which is why, using ASA + PC blend will be a perfect choice to create a UV resistant case or a shell to keep the electronic components protected.

ASA + PC is also great resistant to high heat. Computers tend to generate a lot of heat, and using ASA + PC for computer parts will be a brilliant strategy to make a computer last long.

3.Polycarbonate Plastic

The chemical structure of polycarbonate plastic indicates that it has carbonate groups in it. This makes them a rough and tough plastic type, which is much needed for plastic injection molding of computer parts. Another interesting property of polycarbonate plastic is that it is relatively easy to mold when heated. It’s easy to work with a polycarbonate plastic, which is why many injection molders prefer it.

Computer parts that need transparency, smooth surface finish, durability, and high resistance to heat can be made of polycarbonate plastic while keeping their manufacturing costs controlled.

4.PPE + PS

This group of plastic is very resistant to flame. This means that it has high melting point, which is sure to keep the electronic components safe from heat. In case of fire hazard, computer parts made of PPE + PS are less likely to get damaged quickly.

It shows off impressive hydrolytic stability, which is important in computer parts. Resistance to UV means it becomes an ideal choice for making plastic computer parts at a reasonable price.

5. Polyamide

The polyamide falls under the category of high performance plastic, which is a technical word for nylon. This type of plastic can resist to ultraviolet rays, heat, and electricity. As a result, it becomes a bad conductor or electricity, so there’s no risk of accidental electric shock to the computer users. Households with no ground provision in the building often feel a vibration in their computer parts or even feel a tiny shock sometimes. That happens when the plastic doesn’t resist to electricity well. But that won’t be the case with polyamide plastic computer parts.

Polyamide is further classified in several classes, that are Hexamethylene Diamine/ Azelaic Acid, 1,12-Dodecanediamine/ 1,12-Dodecanedioic Acid, Caprolactum, Laurolactam, etc. The polyamide plastic remains stiff even at high temperatures, so it’s less likely to break down when the computer is used for long hours. As a result, polyamide is preferred for making durable computer parts.

Conclusion

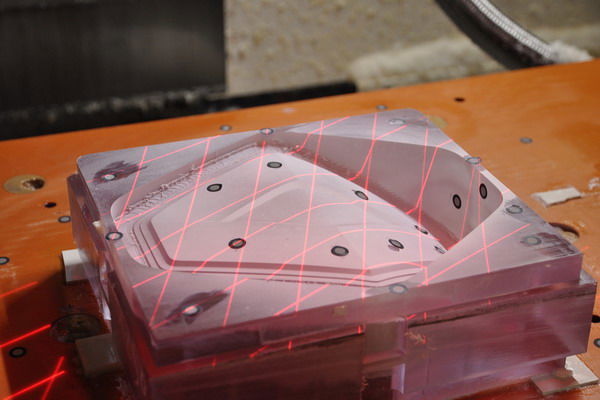

After understanding different types of plastic, their properties, reasons why they’re ideal for use in plastic injection molding specifically for computer parts, you might have also understood why plastic is so favored in making computer parts. The computer parts are heavily made only with the help of plastic injection molding, which is why plastic injection factories and machine manufacturers are much needed in the market in the modern world.