Industries That Rely on Efficient Mechanical Gearboxes

Mechanical gearboxes are the backbone of modern industry. They are critical components in many applications, from powering the massive turbines in energy sectors to driving the conveyor belts in manufacturing plants. These devices translate the raw energy of motors into usable, controlled power. Discover the four key industries that rely on efficient mechanical gearboxes,and gain a greater appreciation for the significance of gearboxes in daily industrial operations.

Automotive Design

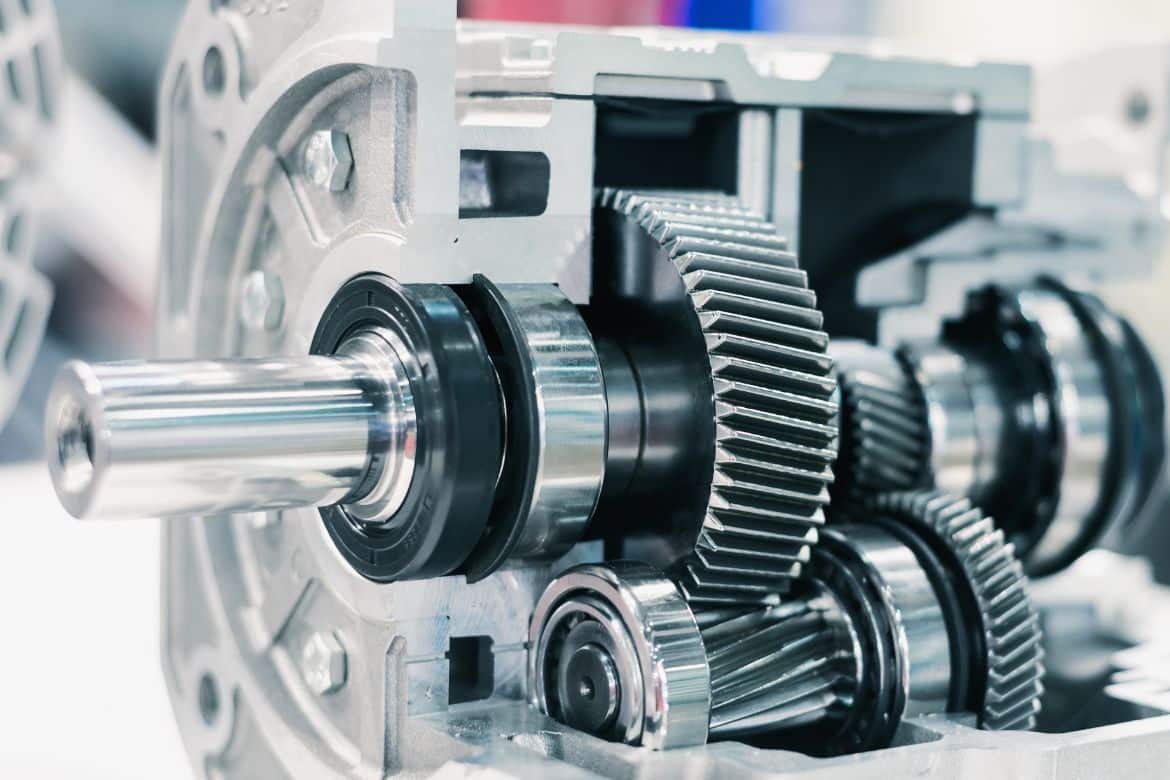

Mechanical gearboxes play a pivotal role in vehicle performance and efficiency within the automotive industry, especially regarding vehicle design. By converting engine power into motion, they enable cars to accelerate smoothly and cruise efficiently at high speeds. Advanced gearbox designs, such as automatic and semi-automatic transmissions, enhance the driving experience by providing seamless gear shifts and optimal power delivery. These factors improve fuel efficiency, reduce wear and tear on the engine, and underline the critical nature of gearboxes in automotive engineering.

Furthermore, the evolution of electric vehicles (EVs) has introduced new challenges and opportunities for gearbox technology. While EVs typically require fewer gears than combustion engine vehicles, the precision and durability of these gearboxes are paramount to utilize the electric motor’s power. Innovations in gearbox design are central to developing more reliable future electric vehicles, showcasing the indispensable role of mechanical gearboxes in the future of automotive design.

Aerospace Design

In the aerospace industry, mechanical gearboxes are vital for aircraft and space vehicle operations, ensuring the smooth transition of power within these complex machines. They play a crucial role in adjusting the speed and torque from the engines to the propulsion systems and other necessary components. They also allow for optimal performance across various phases of flight or space exploration missions. Gearboxes for aerospace must withstand extreme conditions, such as dramatic temperature shifts and intense mechanical stresses, highlighting the importance of durability and precision engineering.

Industrial Manufacturing

In industrial manufacturing, gearboxes are indispensable for maintaining the rhythm and efficiency of production lines. They adjust the speed and torque of conveyor belts and robotic arms with precision. Control is vital for optimizing production processes and facilitating product assembly. By converting motor power into controlled motion, gearboxes enable factory teams to meet high demands while ensuring the safety and accuracy of manufacturing operations. Plant managers can optimize gearbox efficiency through system upgrades and professional consultation.

Mining and Milling

Mechanical gearboxes are integral for extracting and processing raw materials in the mining and milling industries. These devices power heavy machinery—drills, crushers, and conveyor belts—while enabling them to transform solid rock into fine particles and transport these materials over vast distances. Mining equipment gearboxes can endure the harsh conditions of underground environments and continuous operation, optimizing efficiency and reducing downtime. Their reliability and performance are critical for maintaining the flow of operations and ensuring mining and milling activities can meet global demands for natural resources.

Understanding the various industries that rely on efficient mechanical gearboxes empowers professionals to invest in innovative designs that meet their needs. As industries continue to evolve, so too will gearbox technology, further demonstrating its central position in various operations.