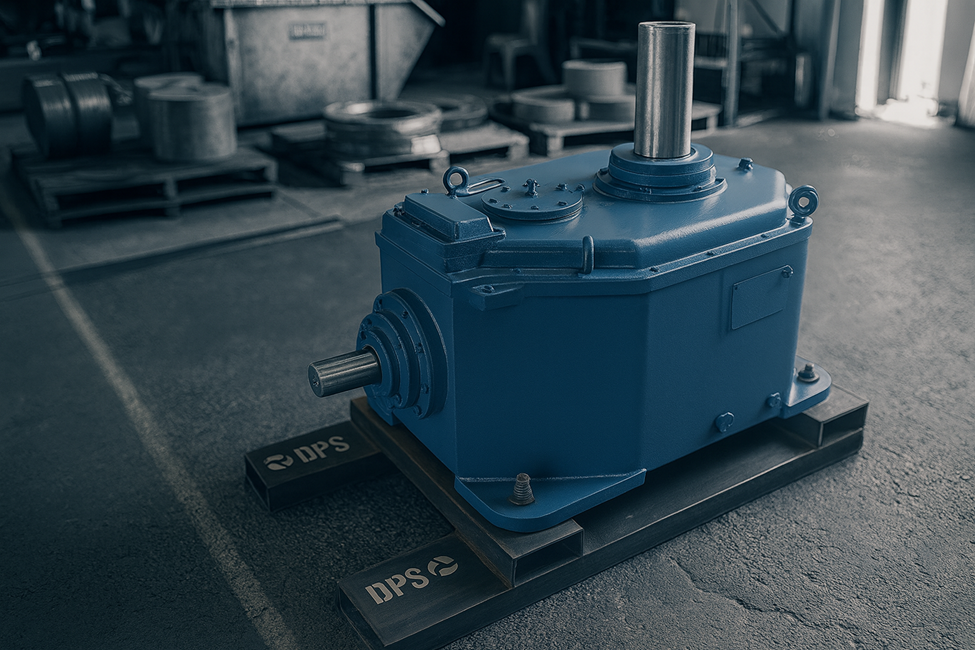

Engineering Solutions for Gearbox Failures in Harsh Environments

If you want gearboxes that keep your operation moving without costly interruptions, you’re in the right place. In this guide, you’ll learn how expert engineering, proactive maintenance, and precision repairs can significantly extend gearbox life in high-pressure environments. With the right approach and the right partner, you can ensure your equipment stays reliable no matter how harsh the conditions get.

Why Gearboxes Fail in Harsh Conditions

Extreme environments expose gearboxes to continuous stress, making them prone to misalignment. Dust, debris, and moisture infiltrate seals and bearings, causing abrasion and corrosion that shorten component life. High operating temperatures accelerate lubricant breakdown, while constant vibration leads to gear wear and alignment drift. Over time, these issues compound, reducing efficiency and increasing the likelihood of sudden failure. Recognising early warning signs such as unusual noise, vibration, or oil discolouration allows maintenance teams to intervene before damage escalates. Understanding these root causes is the first step toward implementing a preventive maintenance plan that safeguards uptime and reliability.

Engineering Solutions That Prevent Downtime

The key to gearbox reliability lies in engineering precision supported by proactive upgrades. High-performance seals, advanced bearing materials, and refined housing designs help keep contaminants out while resisting heat, vibration, and heavy loads. Precision alignment and dynamic balancing further reduce frictional stress, preventing the gradual wear that often goes unnoticed until failure occurs. At the same time, optimised lubrication systems and enhanced cooling pathways ensure temperatures stay within safe limits even in demanding conditions. Together, these engineering improvements strengthen overall durability, extend equipment lifespan, and significantly reduce the likelihood of unplanned maintenance or costly operational interruptions.

Predictive Maintenance and Condition Monitoring

Predictive maintenance turns data into a competitive advantage. Using technologies like vibration analysis, thermography, and oil condition monitoring, engineers can detect early signs of wear long before failure occurs. These systems provide real-time insights into bearing stress allowing teams to plan maintenance when it’s needed most. This proactive approach minimises extended gearbox life. Companies that implement predictive monitoring often see significant reductions in unexpected shutdowns and repair costs. In heavy industrial settings, this technology isn’t just an upgrade but it’s a powerful tool for ensuring consistent performance and operational efficiency.

Partnering with the Right Experts for Long-Term Reliability

When it comes to critical machinery, expertise is the strongest safeguard against failure. Partnering with a trusted provider like Berg Engineering offers complete gearbox manufacture and refurbishment services, including the manufacture and supply of all internal components.. Their team applies advanced diagnostics, precision machining, and condition monitoring to deliver solutions that go beyond short-term fixes. The result is measurable cost savings over time. For industries operating in extreme conditions, working with a proven engineering partner means one thing: reliability you can count on.

Don’t Wait for the Breakdown

Unplanned failures cost far more than the repair bill, they compromise safety on the floor. When a gearbox fails without warning, teams are forced into reactive mode, often facing longer downtime and higher operational risk. Taking action before problems escalate isn’t just smart maintenance; it’s a strategic investment in uptime, safety, and long-term reliability. By staying ahead of early warning signs and strengthening systems proactively, operations can avoid costly surprises and keep equipment performing at its best.