A Simplified Overview of How Laser Tracking Works

When you hear “laser tracker,” your mind might jump to a sci-fi blockbuster with spaceships and high-tech weaponry. While they’d fit right in, laser trackers are very real and their job is less about intergalactic battles and more about incredible precision here on Earth. These devices are the hardworking heroes of modern manufacturing, capable of measuring objects with mind-boggling accuracy.

So how do they pull off these seemingly magical feats of measurement? Read through this simplified overview of how laser tracking works to find out.

A Laser Tracker’s Anatomy

To understand how a laser tracker works, you first need to know its core components. Think of it as a three-part team working in perfect sync.

- The Laser Emitter: This is the heart of the operation. It sends out a focused beam of light, much like a very precise, high-tech flashlight.

- The Target (SMR): Officially called a Spherically Mounted Retroreflector (SMR), this is a special mirrored ball. Its job is to catch the laser beam and reflect it directly back to its source, no matter the angle.

- The Tracking System: This is the brain. It houses sophisticated sensors and motors that precisely control the laser’s direction and interpret the data from the returning beam.

Tracking With Light

The process itself is a clever dance of light and math. The laser tracker locks onto the SMR, which you place on the object you want to measure. As you move the target from point to point, the tracker follows it, continuously measuring two key things: the laser beam’s angle and the target’s distance.

It calculates distance in two ways. First, it uses an absolute distance meter (ADM) for a quick, rough measurement. Then, for hyper-accuracy, it switches to an interferometer. This tool measures tiny shifts in the laser’s light waves as the target moves, allowing it to calculate distance down to a fraction of a human hair’s width. By combining angle and distance data, the tracker builds a 3D map of the object’s surface with incredible detail.

Laser Trackers in the Real World

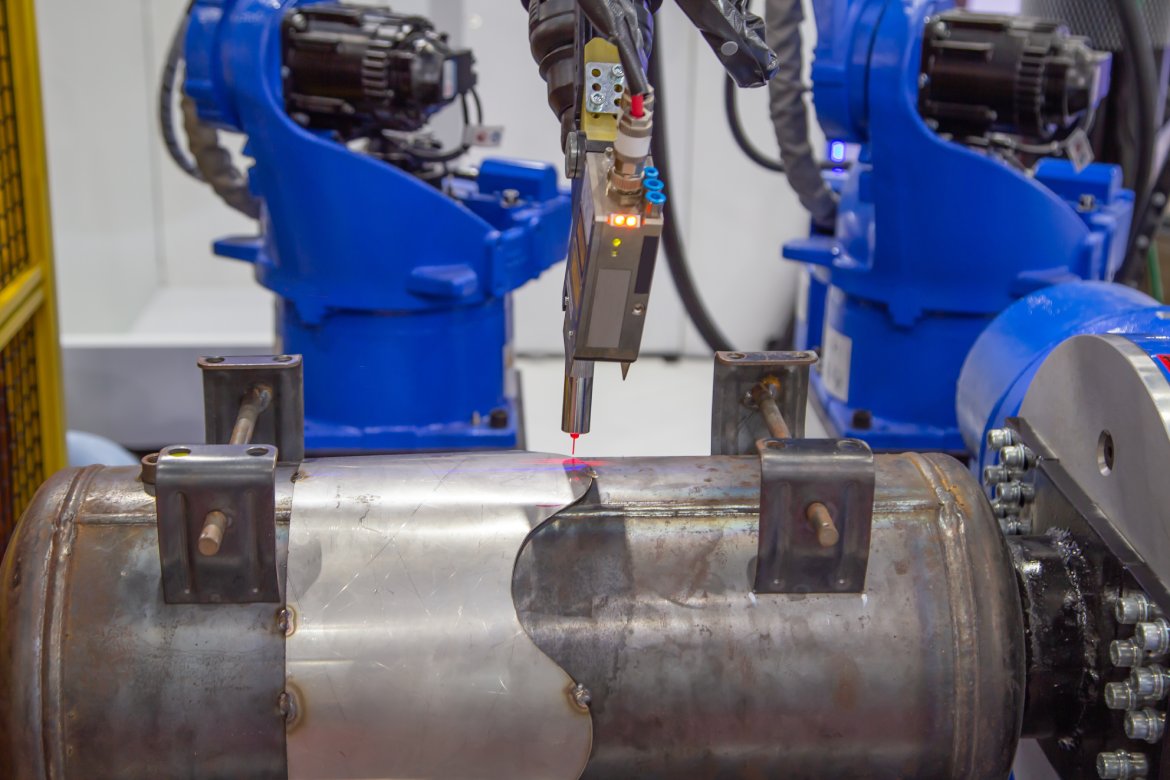

This technology is excellent for the many industries that rely on custom metal fabrication, such as aerospace and automotive manufacturing. For building something complex like an airplane wing or a car chassis, every millimeter matters.

Here, laser trackers improve manufacturing accuracy by ensuring every component aligns perfectly. They check the dimensions of massive parts, verify tool alignments, and make sure everything fits together exactly as designed, which prevents costly errors down the line.

Precision and Efficiency

The biggest advantages of using laser trackers are their pinpoint accuracy and speed. They can capture thousands of data points in minutes, a task that would take hours or even days with traditional hand tools like tape measures and calipers. They are also highly portable, allowing technicians to bring the measurement lab directly to the factory floor.

The Future of Tracking

Laser tracking technology keeps getting better. Future innovations promise even smaller, faster, and more automated systems. We might see them integrated with augmented reality, overlaying digital blueprints onto physical objects in real time.

Laser trackers show how a simple concept—bouncing light off an object—can lead to powerful technological advancements. Far from being just science fiction, they are essential tools that build and shape our modern world with a level of precision that was once unimaginable. With this simplified overview, you now know how laser tracking works and what industries might rely on it.