5 Industries That Use Die Cutting Technology

Die cutting has revolutionized how businesses across different sectors create precise and efficient designs. From crafting intricate patterns to mass-producing essential components, die cutting technology finds its way into a variety of industries.

This innovation proves to be incredibly versatile. Wondering where die cutting makes the biggest impact? Here’s a look at the industries that use die cutting technology and why it’s essential for their operations.

Packaging Industry

Custom designs are key to success in the packaging industry, and die cutting makes it possible. It allows businesses to create unique packaging solutions that stand out on shelves. From sturdy boxes to eye-catching labels, die cutting ensures designs are tailored to customer needs.

For example, think of the perfectly sized inserts in electronic packaging that hold items securely in place. Die cutting creates these with minimal material waste, offering both cost-efficiency and precision. And by understanding the differences between flatbed and rotary die cutting machines, businesses can handle more versatile materials, such as cardboard, plastic, or foam.

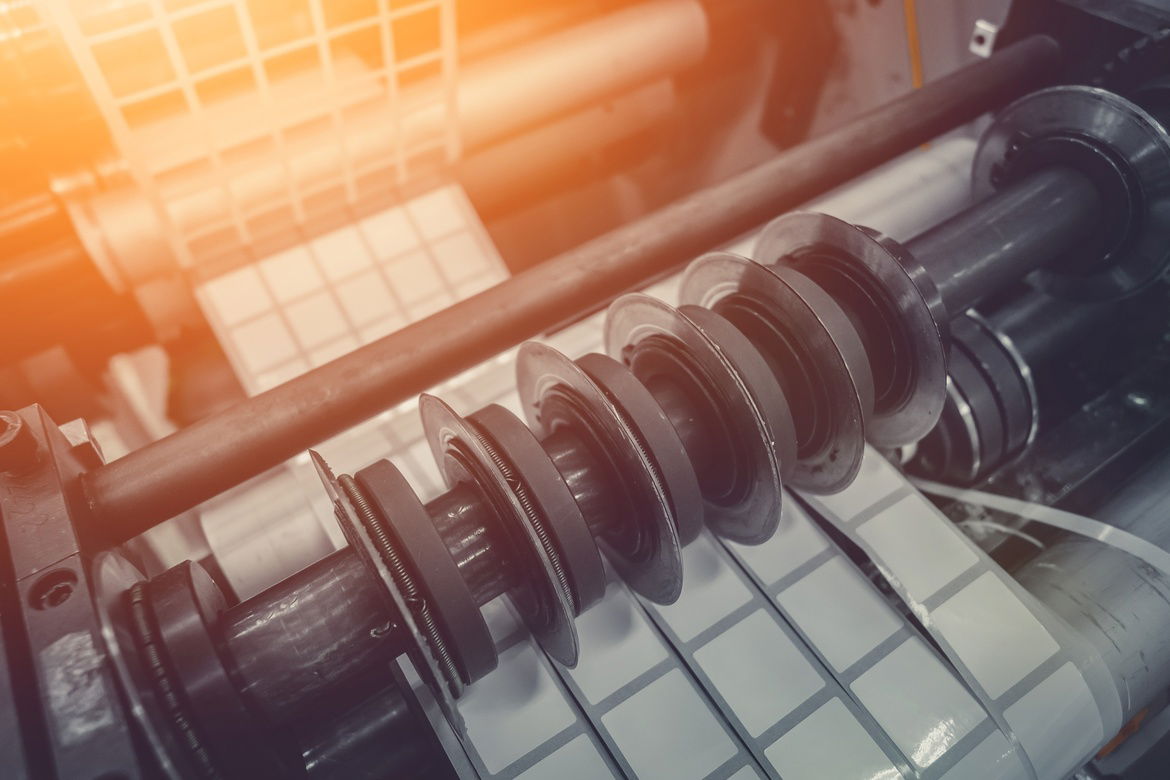

Printing Industry

Die cutting takes printed materials to the next level by adding shapes, textures, and folds that leave a lasting impression. Whether creating elegant business cards with rounded edges or beautifully layered brochures, printing companies depend on die cutting to bring their concepts to life.

For instance, promotional items like pop-up cards or custom-shaped flyers owe their unique designs to the capabilities of automated die cutting machines. Producing high volumes of materials with clean, intricate cuts has never been easier.

Automotive Industry

The automotive field heavily relies on die cutting for manufacturing interior components and functional parts. Essential items like gaskets, seals, and insulation are all made quickly and precisely using die cutting technology.

Even the most popular car interior materials, such as leather and memory foam, benefit from die cutting machines. These machines provide the precision and consistency that’s required throughout the manufacturing process.

Healthcare Industry

The healthcare industry values accuracy and hygiene and die cutting machinery helps medical manufacturers meet both of those needs. It’s widely used to produce vital medical devices, sterile packaging, and disposable supplies like adhesive bandages.

Take surgical masks, for example. Die cutting ensures uniformity in shape and size while meeting strict standards for cleanliness. Plus, rotary die cutting machines allow facilities to produce high volumes of essential medical supplies quickly.

Textiles Industry

Die cutting plays a significant role in the textiles industry by producing uniform cuts in fabrics and other materials. From garments to home textiles like curtains and upholstery, this technology guarantees consistency even in high-volume production.

Think of intricate lace designs or precision-cut leather for handbags. These require a level of detail that manual cutting simply can’t achieve. Die cutting speeds up the process while maintaining the high standards of modern textile production.

The industries that use die cutting technology constantly benefit from its precision, adaptability, and efficiency. Whether it’s enhancing product designs, minimizing material waste, or achieving high-speed production, this technology consistently delivers unmatched value.

If your business belongs to a sector that could harness these benefits, consider integrating die cutting processes into your operations to stay ahead of the curve.