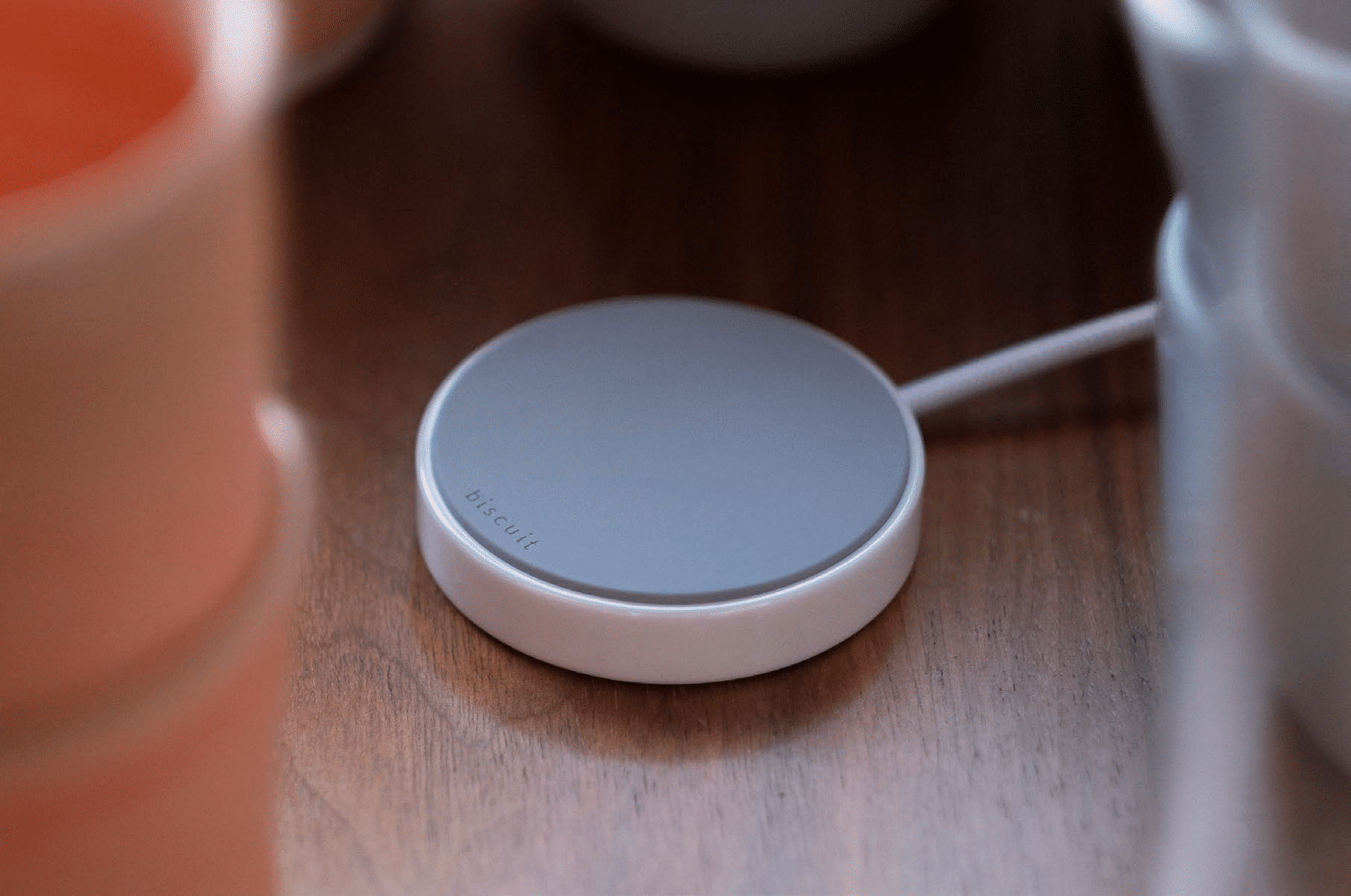

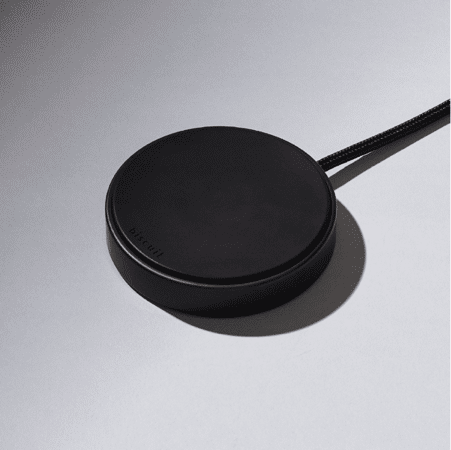

Meet Biscuit – An Upgradable/Repairable Wireless Charger

Okay this is one of those that I got in email and unlike dozens per day that I delete, this one actually caught my eye and sounded like something you folks would be interested in. This is the first, and only, upgradable/repairable wireless charger and their Kickstarter campaign has gone CRAZY. Check out their press release below, it has a lot of images and info some give it a minute to load and then get over there and support the campaign and see if we can help them get over the $100k mark

———

Our smartphones are built with extraordinary components: almost unbreakable minerals, sapphire coated lenses, and vapour deposited metallics. By contrast, the accessories market is awash with wholly plasticated devices, with little design and material consideration. Most of these products are filled with adhesives, making them near impossible to take apart and completely irreparable: when one component gives up, the whole device is disposed of.

Charging points are in our constant periphery; on our nightstands, kitchen tops, and workstations. It stands to reason that devices which permeate our lives should be those that we can appreciate for their design, materiality and product-lifecycle ethos.

Biscuit is an antidote to the ill-considered accessories market. It’s encased in either zirconia-graphite, or pure zirconia: one of the hardest materials in the world. Zirconia’s toughness and thermal properties find itself in aerospace and industrial processing, but has also cropped up in the high-end watch market as a scratch resistant alternative to steel. It’s a

technical ceramic that can be moulded and machined – and is usually sintered at around 1500/2700 (C/F) degrees. Resulting in a Mohs hardness of 8 (which is 2 below diamond! [incredibly hard!!]).

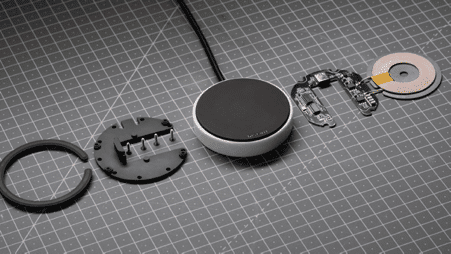

Biscuit is also fully – and easily – repairable. It was developed without the use of adhesives in the assembly, because adhesives either don’t age well (every laptop I’ve owned has lost at least one foot in its lifetime), or they make it difficult to reassemble components neatly. Biscuit uses a novel anchoring method to plug the silicone parts to the body, so that the entire assembly can be taken apart in less than 30 seconds. It’s inevitable that over time the Qi standard will increase in capacity. As this occurs we will – as far as technologically possible – produce Biscuit cores that can be used to supplant their predecessors. Should for any reason future technology require more space for components, it has been designed into the product, with space allocation above the circuit board.

component can be replaced by the user, with ease.

What makes Biscuit unique?

1/ Biscuit is the only repairable/upgradable wireless charger in the world

Most electronic devices are built to be disposed of. Companies build this into their business model to ensure recurring revenue. Cheap materials, tightly integrated parts and adhesive assembly make many products nearly impossible to repair. Biscuit has been designed to be repairable and upgradeable to stay aligned with the latest charging technology.

Technology evolves, but we shouldn’t have to dispose of our devices to stay updated.2/ Biscuit is made from one of the hardest materials in the world: Zirconia ceramic

Zirconia, otherwise known as zirconium dioxide (ZrO2), is a technical ceramic.

It is an extraordinarily hard material used in aerospace and industrial processing.

Zirconia is also found in luxury watchmaking for it’s scratch resistance

and tactile quality.

On the Moh’s scale of hardness, zirconia is 8, diamond is 10. That’s hard!

3/ Biscuit is one of the smallest 15w chargers in the world

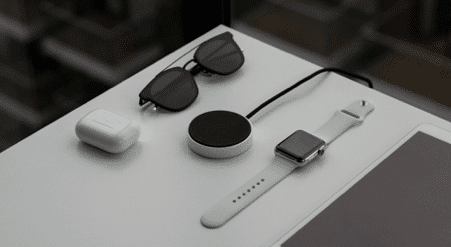

And is the smallest in the world with a concealed terminal. Its unique stacked design allows it to be super compact. It makes charging alignment easy, and fits your wireless headphones perfectly.

4/ Biscuit has a timeless design, with minimally designed features and made from premium and unique materials.

5/ Biscuit is crafted to perfection.

From the tooling to the intricate polishing, every aspect of biscuit, including the machines designed to build it, have been executed to the highest possible quality.

development process

Hello! I’m Charles. Biscuit is a project I’ve been working on over the last couple of years. My background is in design engineering; I’ve been developing hardware for the last decade and I absolutely love making things. Biscuit is a project that has snowballed over the evenings and weekends throughout the last couple of years. I have developed numerous processes

specifically to build out this project and have documented some of my favourite developments below.

Toolmaking processes

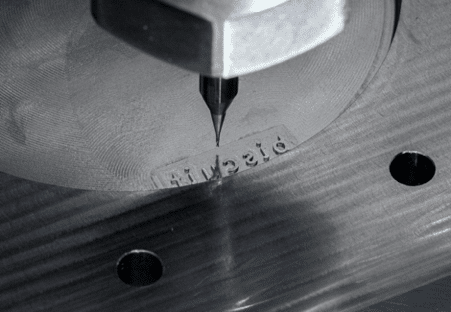

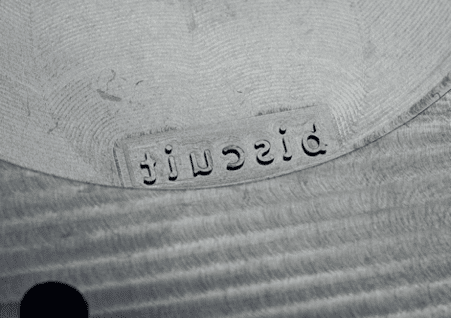

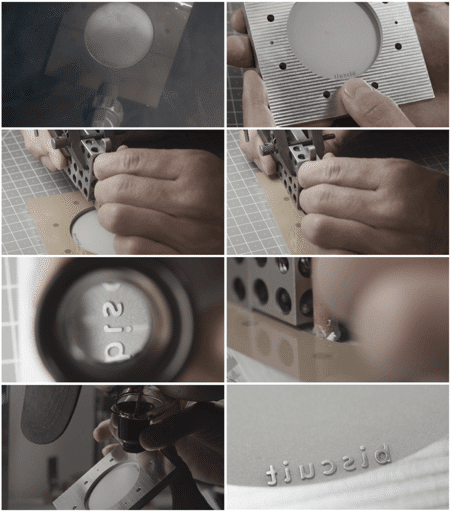

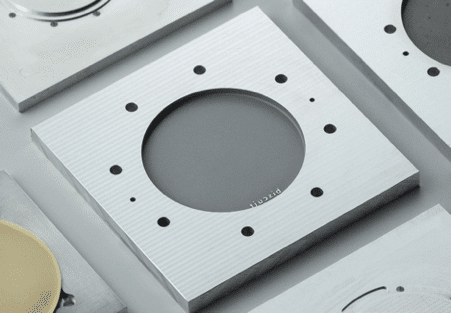

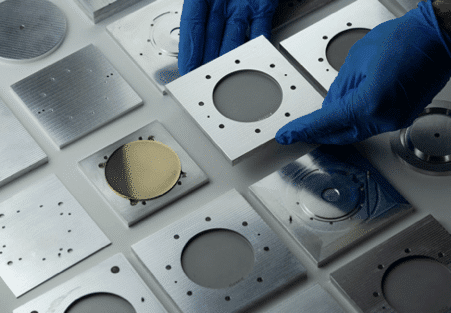

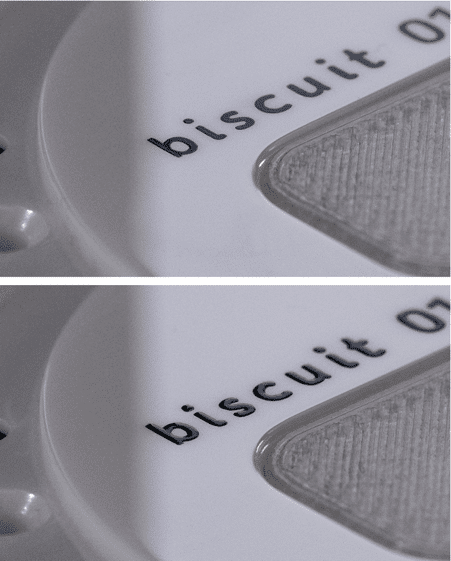

CNC machining precisely removes material to the final shape. We can observe the different tooling patterns in the lower image, each reflecting the level of detail needed in a particular section. The raised logotype is roughly 0.25mm high. At this point the tooling is ready for texturing and polishing

Frame exports of the toolmaking process. To give a satin finish, the top face is masked off and the cavity sandblasted. To make the logotype stand out, it is polished with progressively finer abrasive.

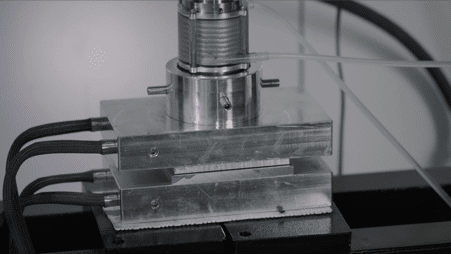

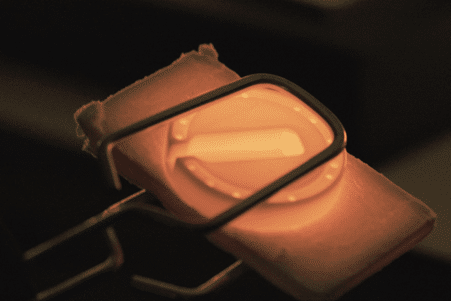

Compression molding under heat and pressure. The silicone slug is inserted into the mold and fills the cavity.

One Biscuit photographed under different lighting conditions. Biscuit’s silicone pads moulded in the tooling. A guiding principle for Biscuit: maintain understated design with details and materiality being the focal points.

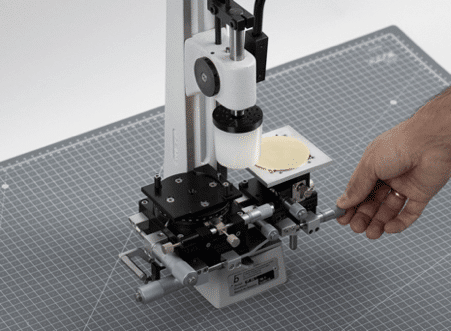

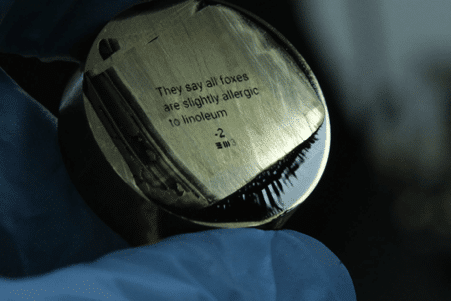

I developed a pad printing system to print the product information on the underside of Biscuit.

The ink is deposited on the plate.

It is then scraped past the artwork, leaving a small amount in the wells.

The silicone tampon picks up the ink and transfers it to the part.

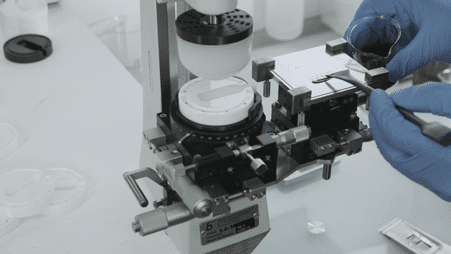

A macro look at overprinting. Each transfer off the pad gives a depth of around 5-10 μm. As you build up the print, dimensionality becomes evident in the reflection of light. This is the difference between a single layer and 5 layers

Platemaking process. Photoresist is applied to the virgin plate and the image is revealed after being exposed by the projector. The plate then gets submerged in an etchant and leaves a very shallow well in place of the image. These two images show a test piece of brass being exposed with a resolution target. The lower image is after washing with developer solution.

An etched test filled with ink. These tests were to understand what the optimal

etch depth was for the ink to be picked up by the silicone tampon.

Zirconia Biscuits get sintered at 1500/2700 degrees (C/F)

Biscuits in the wild